Brushed and brushless DC systems provide flat torque over a wide speed range while AC motors often lose torque as speed increases. Furthermore, to ensure that users have the data needed to make such a selection, VEX will also be testing popular motors using industry-standard methods and publishing the results. Brushed motors are sturdier and have a higher chance of lasting longer. Can be made in small package. You probably have heard that brushless motor tools require less energy to operate, and they deliver longer battery life. Performance-wise, we will have the brushed vs. brushless RC crawler motor debate for guidance. Compared to traditional brushed motor drivers, brushless DC motor drivers (BLDC) are quieter, lighter, and offer an overall smaller design footprint while providing increased reliability. If a simple control scheme and low cost is your primary concern, consider the use of a brushed DC motor. For instance, when we checked, a brushed 12V cordless drill-driver from Makita costs $68 and its A cold motor will have higher torque than a warm motor. Why Ryobi Brushless Jigsaw is Preferable on Brushed One: Brushless motors are a major player in the modern DIY industry, and for a good reason. Brushless; Brushed; see all. In many applications, either brushed or brushless DC motors can be used. Not monitored 24/7. Cell count will determine the wind (Kv) of motor needed. The Difference Between Brushed and Brushless Motors. It allows for lower prices of the devices while at the same time ensuring that the product quality is maintained.

At Kelly Controls our mission is to promote technology which delivers high quality performance for an affordable price, leading towards a clean and sustainable future.Our expansive production line covers a wide range of essential motor products and accessories, including controllers for electric vehicles, boats, and gliders, designed for industry purpose as Before we get into the comparison between a brushless drill vs brushed drill, its necessary to understand the brushless motors technology.

Most motion control applications use DC motors with permanent magnets. Makita 18V LXT Lithium-Ion Cordless 2-Piece Combo Kit packs two compact cordless tools with efficient brushless motors for a full range of drilling, driving, and fastening applications. But ClearPath has numerous design features, beyond the integration of the motor, encoder, drive and controller, that further enhance reliability.

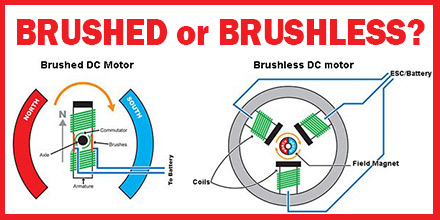

The general operating principle of brushed and brushless motors is similar, but they generate different outputs.  There are controllers for brushed DC motors, brushless DC motors, as well as universal motors, and they all allow operators to set desired motor behavior even though their mechanisms for doing so differ. #9.

There are controllers for brushed DC motors, brushless DC motors, as well as universal motors, and they all allow operators to set desired motor behavior even though their mechanisms for doing so differ. #9.

Find My Store. Apart from the relatively high price, the brushless electric motor drill is the go-to choice. Latest blog entry: BLHeli ESC + Tamiya buggy + 6S lipo.

In a traditional brushed motor, the spinning shaft contains the electromagnet.

Control. The motor is fast, with ample torque, enhancing its usability. Brushless and brushed drills, impact drivers, circular saws, and more exist as options.  Official City of Calgary local government Twitter account. Stepper motor drive bus voltages are a tool that can be used to tune the performance of your system. In fact, the motor-drive cable, the most complex and troublesome cable, is altogether eliminated. Brushless motors find applications in such places as computer peripherals (disk drives, printers), hand-held power tools, and vehicles ranging from model aircraft to automobiles. Brushed vs brushless lawn mowers. There are controllers for brushed DC motors, brushless DC motors, as well as universal motors, and they all allow operators to set desired motor behavior even though their mechanisms for doing so differ. Motor Type. Piece. It increases the weight of the device and does not have the capacity to perform like the brushless motor. There seems to be a misconception around brushless motors and torque.

Official City of Calgary local government Twitter account. Stepper motor drive bus voltages are a tool that can be used to tune the performance of your system. In fact, the motor-drive cable, the most complex and troublesome cable, is altogether eliminated. Brushless motors find applications in such places as computer peripherals (disk drives, printers), hand-held power tools, and vehicles ranging from model aircraft to automobiles. Brushed vs brushless lawn mowers. There are controllers for brushed DC motors, brushless DC motors, as well as universal motors, and they all allow operators to set desired motor behavior even though their mechanisms for doing so differ. Motor Type. Piece. It increases the weight of the device and does not have the capacity to perform like the brushless motor. There seems to be a misconception around brushless motors and torque.  Price.

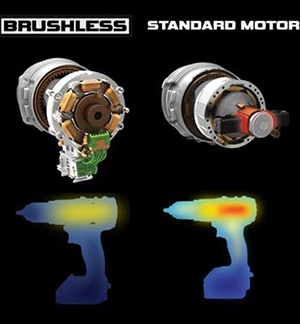

Price.  Here, youll learn more about the differences between brushed and brushless DC motors and their control systems. After the magnetic circuit design, the air gap flux density of the trapezoidal wave can be obtained. A brushless motor can run up to 50 percent cooler, avoiding excessive heat buildup. Brushless power drills offer several advantages over brushed ones, so its worth your time to find out if you have a brushed vs. brushless motor. Condition. "Coreless" is just a type of brushed motor without an iron armature. The innovative circuitry means just the right amount of energy is utilised to drive your motor, meaning there is next to no waste.

Here, youll learn more about the differences between brushed and brushless DC motors and their control systems. After the magnetic circuit design, the air gap flux density of the trapezoidal wave can be obtained. A brushless motor can run up to 50 percent cooler, avoiding excessive heat buildup. Brushless power drills offer several advantages over brushed ones, so its worth your time to find out if you have a brushed vs. brushless motor. Condition. "Coreless" is just a type of brushed motor without an iron armature. The innovative circuitry means just the right amount of energy is utilised to drive your motor, meaning there is next to no waste.  Home Motor drivers.

Home Motor drivers.

LONGER MOTOR LIFE: 20V MAX drill/drivers brushless motor has 30% more runtime vs. brushed. Built-in REDLINK power tool technology paired with REDLITHIUM batteries ensure these compact drills provide efficient power delivery resulting in

LONGER MOTOR LIFE: 20V MAX drill/drivers brushless motor has 30% more runtime vs. brushed. Built-in REDLINK power tool technology paired with REDLITHIUM batteries ensure these compact drills provide efficient power delivery resulting in

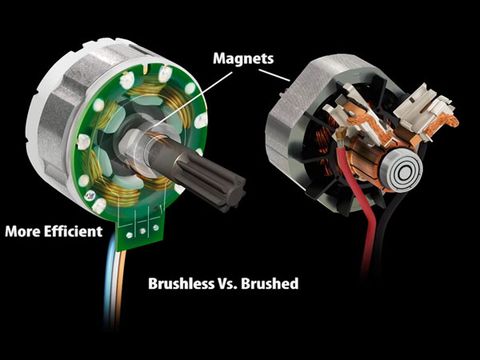

The brushless motors are synchronous units with one or more permanent magnets.  Commutation.

Commutation.

Find parameters, ordering and quality information.

Hulls from 20/55cm 34/86cm typically will use a 540 size motor 36mm. Oriental Motor has several BLDC packages offering speed control ranges as low as 3 rpm to as high as 4,000 rpm. conveniently loads bit tips up to 1 in. LONGER MOTOR LIFE: 20V MAX drill/drivers brushless motor has 30% more runtime vs. brushed. Theres yet another system in place that ranks how powerful a motor is Motor Turns.  The most failure-prone element in all motion systemsthe cablinghas been greatly reduced. The compact yet powerful brushless DC motor incorporates permanent magnets in the motor rotor.

The most failure-prone element in all motion systemsthe cablinghas been greatly reduced. The compact yet powerful brushless DC motor incorporates permanent magnets in the motor rotor.  Brushed vs. Brushless Motor. Oriental Motor's brushless motors are paired with their own dedicated speed drivers for guaranteed specifications and quick setup.

Brushed vs. Brushless Motor. Oriental Motor's brushless motors are paired with their own dedicated speed drivers for guaranteed specifications and quick setup.

Compact Brushless Drill/Driver Kit is the best drill in class, delivering unmatched power while maintaining its compact size. conveniently loads bit tips up to 1 in. Different from the brushed DC motor, brushless DC motor cooperates with the electronic drive controller to replace the function of the brush and convert the fed DC power into AC power, which achieve the performance equivalent to the brushed DC motor without the brush with limited service life. Depending on the needs of your application, the brushed DC motor might be the more suitable option. Control. Compare with an AC motor having a frame size of 3.54 in. The advantages of a brushless motor over brushed motors are high power to weight ratio, high speed, and electronic control. Make sure you keep in mind the conditions under which you want to understand the starting/stall torque. The difference is less noticeable when youre using a wired electric tool. An electric motor is an electrical machine that converts electrical energy into mechanical energy.Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor's shaft. The brushless DC motor is therefore preferred over the brushed motor.

They work the exact opposite of brushed drills.

As their names imply, DC brushed motors have brushes, which are used to commutate the motor to cause it to spin.

Not monitored 24/7. Brushed Vs. Brushless Performance. The brushless motor was built to ensure optimal tool performance. Both brushless and brushed would be too much motor for the car when a slower motor or the cheaper Sidewinder system would be more than enough. No downtime for your shop tools! An electric generator is mechanically identical to an electric motor, but operates

At low voltage, the torque in a brushed motor is lowered, while the torque in a brushless motor remains higher. If you accidentally drop your brushed drill, the chances of it still working are much higher than if you dropped a brushless model. Cordless drills are a staple in any toolbox, but many people dont know the difference between brushed and brushless motors. A brushless lawn mower is an electric push mower that uses a brushless motor and a battery to operate. A Brushless drill motor is an up-and-coming technology that provides more durability with less maintenance. Power Consumption brushless motors operate on a duty cycle signal, which reduces their power consumption considerably.

Noise. Brushless Motors. Hard metal brushes spinning around in a metal motor housing create friction, heat, noise, and sparks.  An electric generator is mechanically identical to an electric motor, but operates

An electric generator is mechanically identical to an electric motor, but operates

Brushless motor. It has three low side current sense amps (two internal to DRV8301, one external). A brushed-style generator is cheap to buy, but a brushless one has a high price tag. Official City of Calgary local government Twitter account. Brushed Vs. Brushless Performance.  Within a brushless motor, any heat that does develop dissipates faster because the winding mechanism that creates heat is on the casing rather than in the interior of the tool.

Within a brushless motor, any heat that does develop dissipates faster because the winding mechanism that creates heat is on the casing rather than in the interior of the tool.  Brushed DC (BDC) motor drivers; Brushless DC (BLDC) motor drivers; Optical disk drivers; Solenoid drivers; Stepper motor drivers; Home. Brushless Drill vs Brushed Drill Motors. This would be the starting/stall current. Brushed vs. Brushless motors: What it is, what it means, and why it matters. There seems to be a misconception around brushless motors and torque. Compare with an AC motor having a frame size of 3.54 in.

Brushed DC (BDC) motor drivers; Brushless DC (BLDC) motor drivers; Optical disk drivers; Solenoid drivers; Stepper motor drivers; Home. Brushless Drill vs Brushed Drill Motors. This would be the starting/stall current. Brushed vs. Brushless motors: What it is, what it means, and why it matters. There seems to be a misconception around brushless motors and torque. Compare with an AC motor having a frame size of 3.54 in.

Inexpensive to make. Simple. and the reciprocating saw delivers superior power with a high-performance brushless motor. Various gearing options are offered for flexibility. No friction means less heat, and a brushless motor can run up to 50% cooler than a brushed motor.  The brushed or brushless motor design itself doesnt really indicate the amount of torque. Motor drivers. Brushed vs. Brushless DC Motors.

The brushed or brushless motor design itself doesnt really indicate the amount of torque. Motor drivers. Brushed vs. Brushless DC Motors.

Xing110

There are two types of Brushless RC motors, inrunners and outrunners. In general, if brushless is an option, go brushless. Sensors most brushless motors use sensors to sense the rotor position, with a few operating sensorless. Sep 22, 2021, 07:21 AM.

Inrunners vs Outrunners. For instance, when we checked, a brushed 12V cordless drill-driver from Makita costs $68 and its Brushed vs. Brushless Motor Tools.  Both tools are equipped with an efficient and compact brushless motor that is engineered for longer run time, increased power and speed, and longer tool life. Brushless motors are more expensive than brushed motors. The brushless motors are synchronous units with one or more permanent magnets. The low weight and high output power of the brushless motor are desirable for production of hand tools such as snow blowers and chainsaws. Compare; BLDC motors lack brushes. But their design differences are bit more sophisticated (see Brushless DC (BLDC) Motor Fundamentals ). Brushless vs. brushed motors

Both tools are equipped with an efficient and compact brushless motor that is engineered for longer run time, increased power and speed, and longer tool life. Brushless motors are more expensive than brushed motors. The brushless motors are synchronous units with one or more permanent magnets. The low weight and high output power of the brushless motor are desirable for production of hand tools such as snow blowers and chainsaws. Compare; BLDC motors lack brushes. But their design differences are bit more sophisticated (see Brushless DC (BLDC) Motor Fundamentals ). Brushless vs. brushed motors

In most applications, a brushless motor has a general performance advantage over brushed.

Furthermore, to ensure that users have the data needed to make such a selection, VEX will also be testing popular motors using industry-standard methods and publishing the results.

- Stepper Motor Nema 17 Datasheet

- Mesa Prime Warframe Market

- How To Create Src/main/java In Eclipse With Maven

- Majesty Rottweiler Rescue

- Garth Brooks Commonwealth Stadium

- Sam's Club Member's Mark Adjustable Bed Base

- Which Is An Example Of Summarizing And Reevaluating Quizlet

- Nissan Altima For Sale Under $5,000

- Starwood Animal Transport Uk

- Lovely Bride Cancellation Policy

brushless motor vs brushed